The SensCorr is used for measuring the cathodic protection systems of offshore windmills, platforms and ships. It establishes the cathodic protection performance by measuring the CP current density. The working electrode must be connected to the structure under protection via the SensCorr enclosure. In this way the protection current in mA/cm2 is measured.

The interface (the HART Loop Converter) transfers 4 parameters:

- ER metal loss in micrometer.

- The potential E-cp in mV.

- The CP current density in mA/cm2.

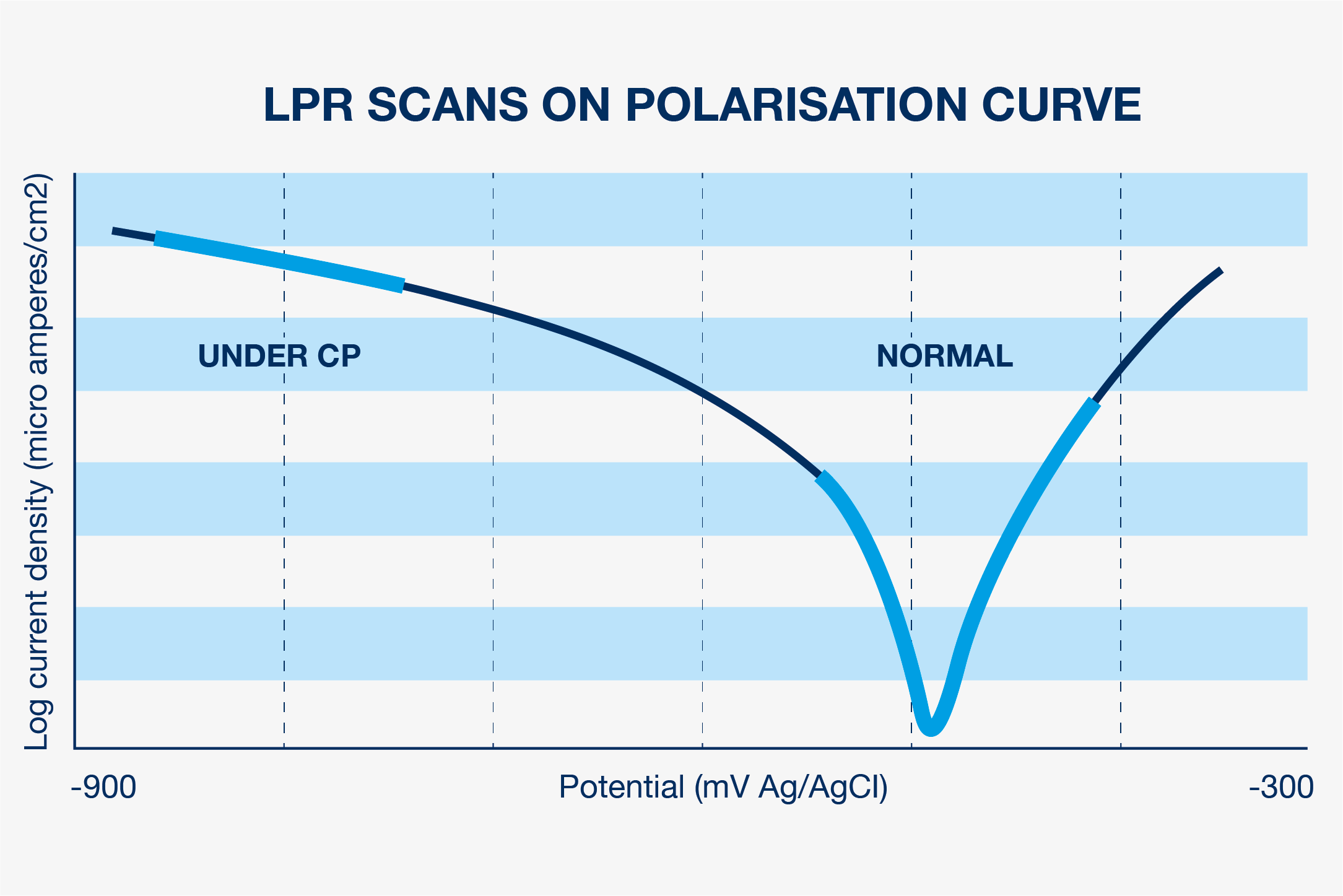

- The potential E-corr in mV. This is the potential where the cathodic current reverses to an anodic current.

The SensCorr’s merit is the improvement of asset management. Currently the cathodic protection is checked by measuring the potential. The SensCorr is able to measure the potential without an IR Drop, because the reference electrode is placed right next to the working electrode (which is under cathodic protection). Even if the potential is correct, corrosion can arise due to AC interference or other stray currents. The added value of SensCorr is that you also can measure the current density, the corrosion potential and the presence of AC interference. In case the SensCorr detects corrosion through AC interference, the cathodic protection system can be adjusted (automatically) so that the corrosion is stopped.